R&D & Intelligence

R&D capabilities

The Xusheng Group has independent research institutes, technology centers, specialized process centers, automation equipment centers, testing centers, and laboratories. These facilities facilitate comprehensive research in materials, mold design, process innovation, and product development.

The Group has received numerous accolades and recognitions, including the National High-tech Enterprise, National Enterprise Technology Center, National Demonstration Enterprise of Manufacturing Champion in Individual Fields, National Intellectual Property Demonstration Enterprise, Provincial High-tech Enterprise Research and Development Center, Zhejiang Famous Brand Product, Zhejiang Enterprise Research Institute, Ningbo Technology Innovation Team, and the Science and Technology Progress Award.

The company has domestic and foreign top development application software and has synchronized development as well as independent research and development capabilities, including but not limited to:

Product design: UGNX, CATIA CAD

Mold design: UGNX;

Mold CAE simulation: MAGMA, FLOW 3D, Qform.

As well as structural CAE simulation, thermal management CAE simulation development capabilities.

In the product lightweight design, structure simulation and optimization has accumulated rich experience; in the field of material self-research, has a number of invention patents, material standards can basically cover the mainstream OEM standards; in the field of high-precision molds and large-scale mold design and manufacturing, the company by virtue of the technological basis and first-mover advantage, is in the industry at a leading level. Currently, the independent design and manufacturing capacity of molds can fully meet the business needs of die-casting, forging, extrusion, etc., and can provide professional technical support and assistance to peers and associations.

The group has an independent research institute, technology center, special process center, automation equipment center, testing center and laboratory.

3D printing of molds, local extrusion, high-pressure cooling, vacuum valves, etc. vacuum valves, etc.

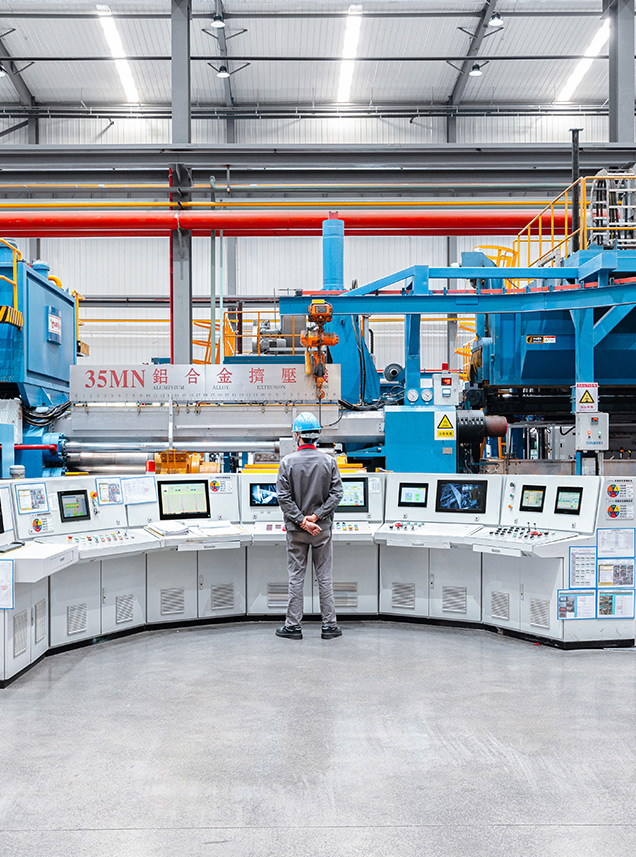

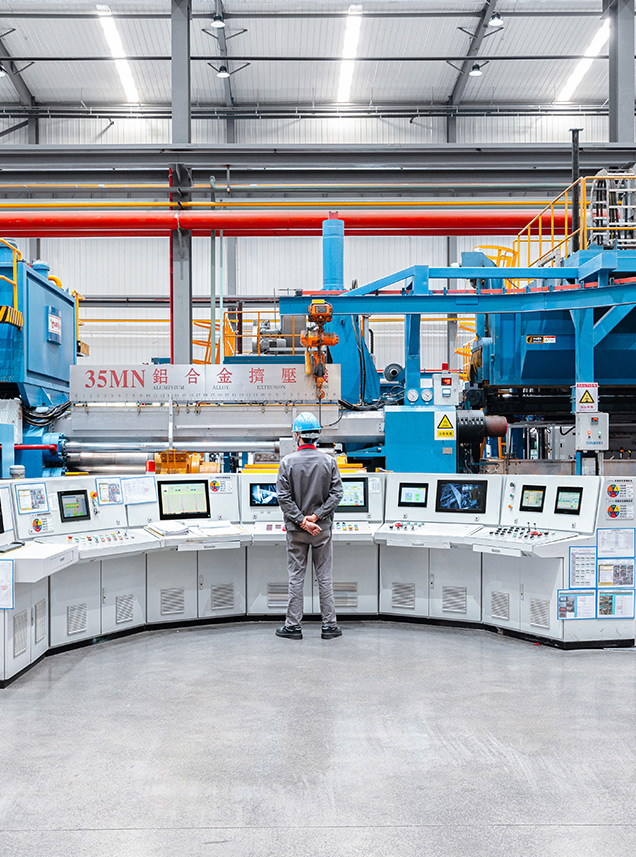

Die casting machine tonnage covers the range of 210T-9000T

Products can realize T4, T5, T6 and T7 heat treatment, suitable for all kinds of structural parts die-casting products

With online dehydrogenation Wagstaff casting tube filtration technology, casting rods can realize horizontal and vertical casting, and realize 100% automated ultrasonic flaw detection and 100% fluorescence detection, the company has 6500T imported forging production line, the use of high-efficiency heat treatment equipment in line with AMS2750 and CQI-9.

Through self-developed material composition to improve the mechanical properties of the material, the company has a gradient heating frequency furnace for aluminum rods, liquid nitrogen cooling technology for molds and T4, T6, T7X multiple aging process to regulate the material properties, self-developed materials have been awarded a number of invention patents.

FSW welding, laser welding, CMT welding trajectory tracking automatic correction technology, and has obtained a number of invention patents

The Group's automation center independently and autonomously designs on-line automatic scanning, on-line laser inspection, on-line CCD inspection and other technologies, and has obtained a number of invention patents.

Coverage of direct pressure, differential pressure, flow, vacuum and water, gas and helium detection techniques.

Independent process equipment design and CNC machining technology, covering five-axis, four-axis, composite CNC machining high-precision machining design technology, has obtained a number of patents

Covers SPR, FDS, dispensing, riveting, riveting, and automated assembly technologies.